The product features a new modular approach to system design, which introduces additional flexibility in configuration, allowing the required capacity to be reached by combining smaller units piped together and controlled as one.

Consisting of three base modules with capacities of 100, 125 and 160kW, the range features Daikin design scroll compressors and R-32 refrigerant, whose GWP is 70% lower than that of R-410A.

As well, R-32, being a pure and single component refrigerant, has all the characteristics needed to be easily recovered, recycled, or regenerated, so to enter the reclaimed refrigerant market and be reused.

R-32 is also widely available on the market, as main refrigerant for air conditioning units with scroll compressors. That is, largely available for maintenance services.

3 product versions

- Heat pump with inversion on water side

- Heat pump with inversion on refrigerant side (100 kW only)

- Condenser-less

3 base modules

- 100 – 125 – 160 kW

98 possible combinations of modules

with the different product versions

Capacity range

Three base modules of 100, 125 and 160 kW.

Modules can be combined up to 8 in two stacked arrays of 4, with resulting capacity range from 200 to 1280 kW

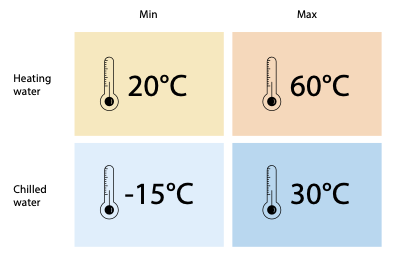

Operating range

Product Benefits

Scalability & compactness

Due to its modularity, the new EW(W)(H)(L)T-Q A units offer high scalability potential. Modules can be added when needed, according to building’s construction plan.

As well, modules can be combined as a side-by-side array or stacked to minimise space requirements, particularly useful for retrofit applications. Modules can be combined up to 8 in two stacked arrays of 4, with resulting capacity range from 100 to 1280 kW.

Max horizontal array: 4

Stackable up to 8 modules

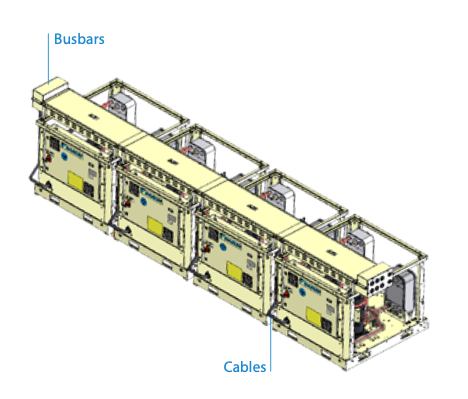

Single Power Supply

As standard (no accessory) each module must be connected to a separate power supply. It is possible to have a single array (up to four modules) with a single power supply.

Busbars and cables are provided by factory with one of the below accessories codes. The electrical connection between modules must be done on site.

Accessory codes:

EKSPELT2 - Single Power Supply Kit for 2 modules

EKSPELT3 - Single Power Supply Kit for 3 modules

EKSPELT4 - Single Power Supply Kit for 4 modules

Attention:

- Single Power supply kit is shipped loose and to be mounted on site J The stacked installation is not compatible with single power supply configuration

- Single power supply available only for indoor installation

- In case of 4 units on order, to be arranged in array, in case single power supply is required, EKSPELT4 can be selected just one time

Plug & play installation

Simplified installation with the Manifold Kit, which is designed to connect modules on the waterside, as it includes the pipework between the units. The Manifold Kit can also be factory-mounted to further reduce installation time on site. In addition, a dedicated Pump Module can be easily added to the array of modules. It is equipped with inverter pumps for full flexibility and includes an 18-litre expansion tank. For further easiness of installation, Single Power Supply can be integrated, having 1 single power cable connected to the array of up to 4 modules (cables connecting modules provided by factory).

The modules can be installed indoor or even outdoor, if the reduced noise configuration would be selected. Indeed, the new EW(W)(H)(L)T-Q A offers two different noise configurations to comply with the requirements of noise sensitive applications as: residential, hotels and hospitals.

Lower operating costs

Thanks to its modular design, this new unit can closely follow the cooling and heating load profile of the building, according to EN14825. This is particularly important as it ensures low operating costs for the HVAC system at part load conditions, which represent most of the operating time. This is not the case with traditional packaged chillers & heat pumps, that need to work on a series of on-off cycles, reducing system efficiency.

Contribution to Green Building

The most popular green building protocols are BREEAM and LEED. EW(W)(H)(L)T-Q A can contribute to a project’s credits when evaluating energy efficiency of the hydronic system, especially

if Partial Heat Recovery option would be selected. The limited GWP of R-32 and the low refrigerant charge per circuit thanks to the modular design also result in a possible contribution when evaluating the impact of refrigerants.

Limited environmental impact

The units use R-32 refrigerant, which has a Global Warming Potential (GWP) of 675, just one-third of R-410A. R-32 is

a pure and single component refrigerant, so it can be reclaimed. A recent study from Tokyo City University* reports that reclaimed R-32 has an environmental impact 90% lower than virgin R-32, due to avoided need of destruction and lower energy required for reclamation with respect to new production. Daikin uses reclaimed R-32 on its chillers and heat pumps under its Loop by Daikin programme.

Product Applications

Heating

Space Heating + DHW configurations

- Centralized heating, eventually in water loop cascade with an air to water heat pump. DHW supply managed via independent DHW supply (single or array of modules dedicated to DHW, eventually stacked). Units can be managed in master / slave up to an array of 4 modules per master

- Residential, offices, Light commercial, gym, hotel

- Replacement and new building

- Possible terminals:

- Radiators (up to 60 °C)

- Heating floor (30-35 °C)

- Fan coils (45 °C)

Cooling

Comfort cooling

Centralized cooling. DHW managed via independent DHW supply (single or array of modules dedicated to DHW, eventually stacked). Units can be managed in master / slave up to an array of 4 modules per master

- Residential, offices, Light commercial, gym, hotel

- Replacement and new building

- Possible terminals:

- Coolingfloor(23-18°C)

- Fancoils(12-7°C)

Process cooling

- Dedicated or centralized cooling according to project’s needs. Units can be managed in master / slave up to an array of 4 modules per master

- Milk cooling (9-4 °C)

- Refrigerated warehouse (-8 to -12 °C, with glycol)

- MRI cooling, and many others

Learn more

-

ECPEN24-470 Water to Water Modular Chillers and Heat PumpsPDF | 972.31KB

ECPEN24-470 Water to Water Modular Chillers and Heat PumpsPDF | 972.31KB